In a manufacturing process in an industrial environment, the industrial weighing or dosing of products must be carried out very accurately. There are therefore specific weighing/dosing systems that guarantee the accuracy of these operations. SCCM ALP provides turnkey solutions for these problematics.

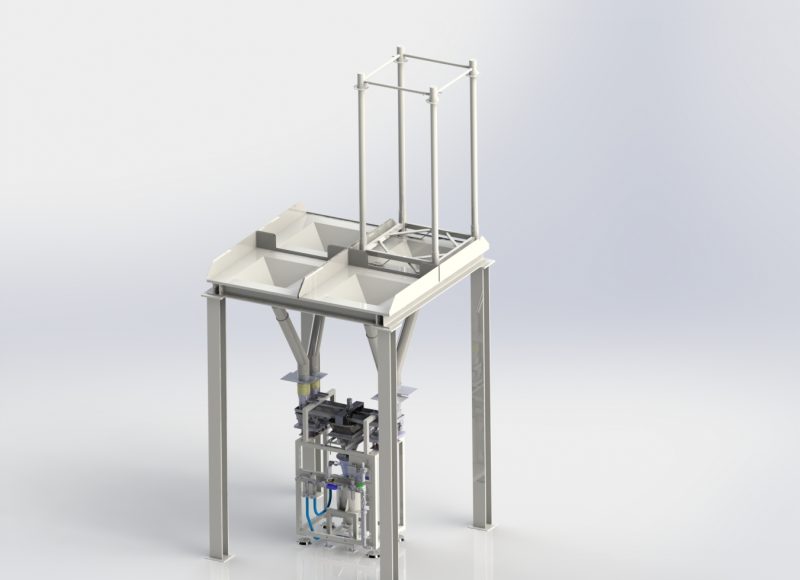

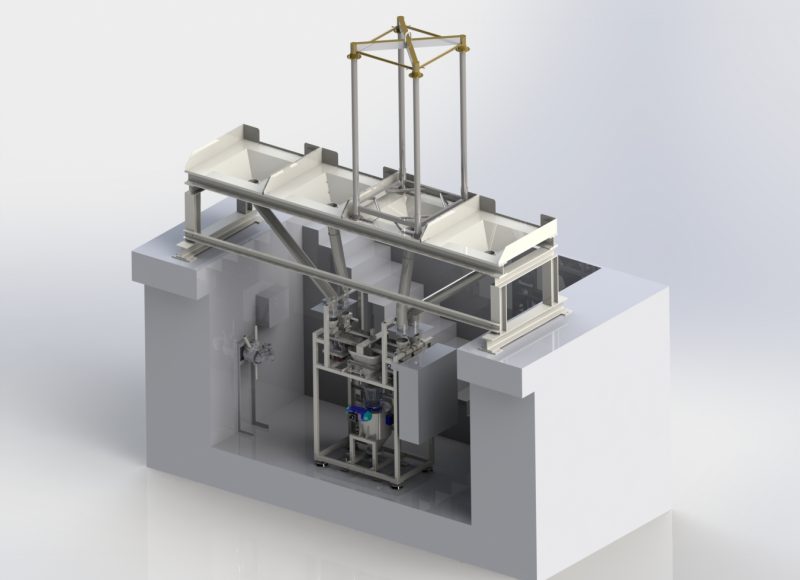

Powder Dosing

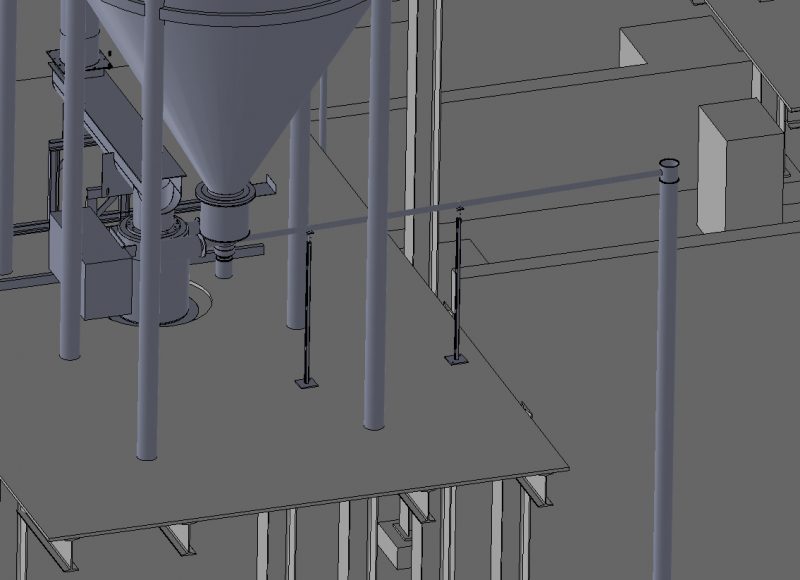

The powder dosing stands are used by the concrete batching plants to dose the coloring of their concrete as well as by the manufacturers of outdoor fittings.

The powder and granule dosing and transfer station is equipped with :

- 1 to 5 independent vibration systems

- a hopper weighed with an accuracy of +/- 5%.

- A SAS air expedition system

Powder dosing stands are used for the precise dosing of different powders.

Totally autonomous, an electric and pneumatic power supply is sufficient for their operation.

SCCM ALP has developed its own turnkey solution.

Advantages:

- Fully customizable: different layouts (in line or square)

- Loading by big bag or by bags, for 1 or more mixers

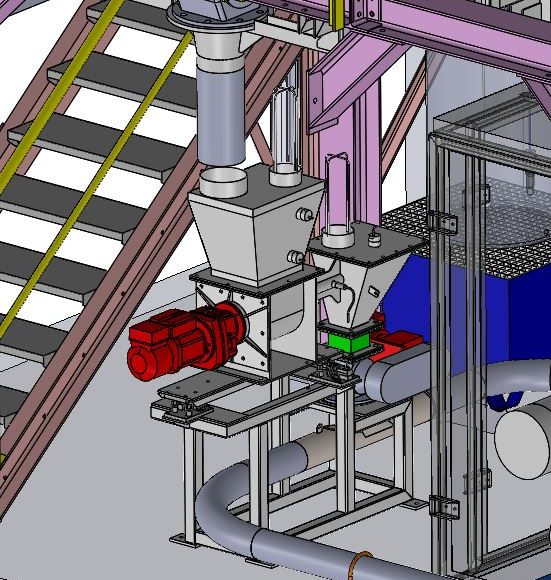

Micro-dosing

Volumetric dosing unit for continuous process for powder or granules with a small dosing volume (max. 10kg/h). It is fully equipped:

- a dosing screw dimensioned according to the required flow rate and

- an integrated lump breaker (geared motor)

- a buffer hopper with its level sensors

It can also be equipped with an alveolar SAS (sluice) and a gearbox at the screw outlet in order to connect the microdoser directly to a pneumatic transport line, a scale for flow control or even, as equipment for a big bag unloader.

Delivered ready to use, just install it and connect it electrically.

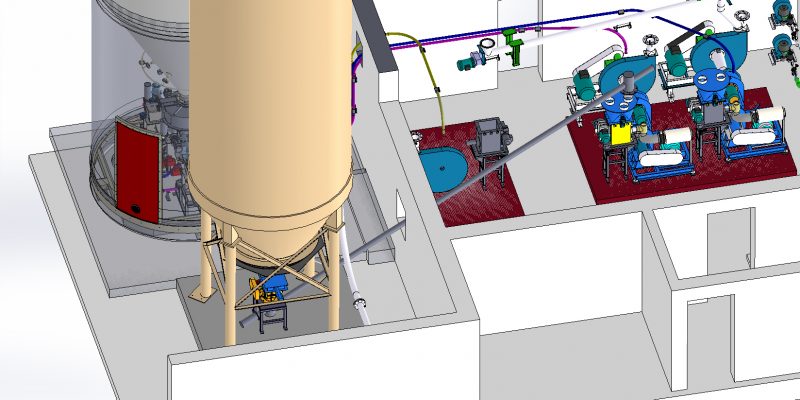

Screw

This equipment is designed for large dosing volumes and can also be used to transfer all types of products (abrasive, small granulometry…) in incineration plants, cement factories, but also in the pharmaceutical field with different designs: worm screw with or without core, with or without bearing depending on the function and the product.

Made of stainless steel or steel, the transfer screw can be equipped with one or more inlets and outlets to meet the customer’s needs.

Also available in food quality finish, in ATEX version, the screws are adapted according to the constraints imposed.