SCCM ALP water-cooled, long-life equipment for arc furnaces (EAF), blast furnaces and secondary metallurgy industries are designed to provide an economical and qualitative solution. SCCM ALP strives to provide high quality while guaranteeing the shortest possible delivery times. These products enable steel manufacturers to achieve a real gain in competitiveness.

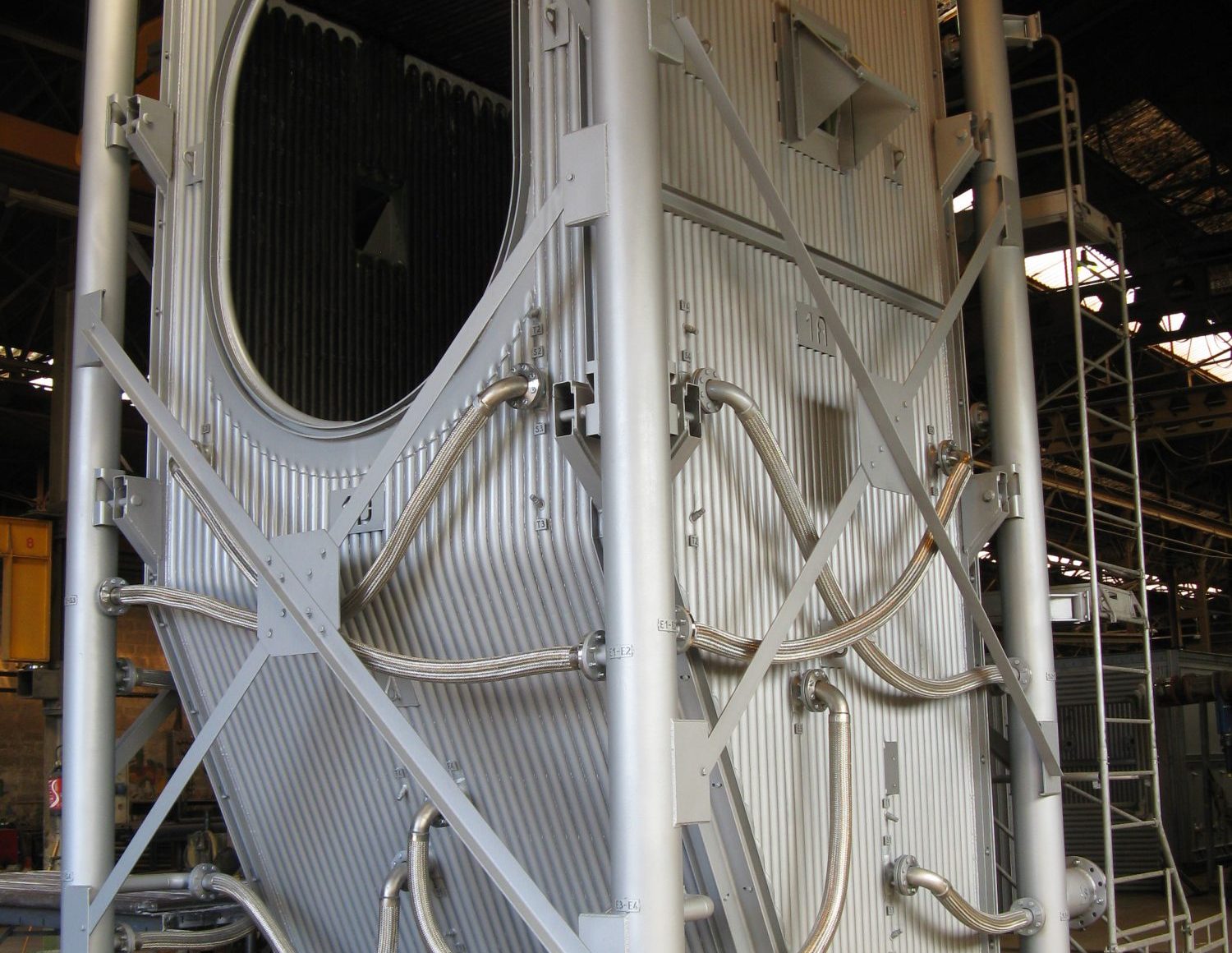

In addition to its technological “savoir-faire” of the manufacture of water-cooled elements (panels, ducts, vaults…), SCCM ALP stands out for its mastery of thermomechanics, which enables it to design its water-cooled products based on the characteristics of your installation, maximising thermal exchanges and preserving your infrastructures.

Many production stoppages or even serious accidents in steelworks are caused by the failure of water-cooled components. The production continuity of a plant is considerably increased when SCCM ALP water-cooled elements are installed.

Based on more than 30 years of experience in this tubular technology and more than 60 years in double jacket technology, SCCM ALP has accompanied the move up-market required by steel manufacturers.

As a fully integrated company, SCCM ALP is committed to reaching this level by designing and manufacturing water-cooled panels and equipment at its French site in Chambéry.

We also control the material origins and the entire supply chain for our steel, carbon and copper tubes.

Our welding qualifications and quality procedures enable us to guarantee a very high level of reliability, as well as rigorous monitoring of our production schedule enables us to meet customer deadlines.

Our water-cooled elements:

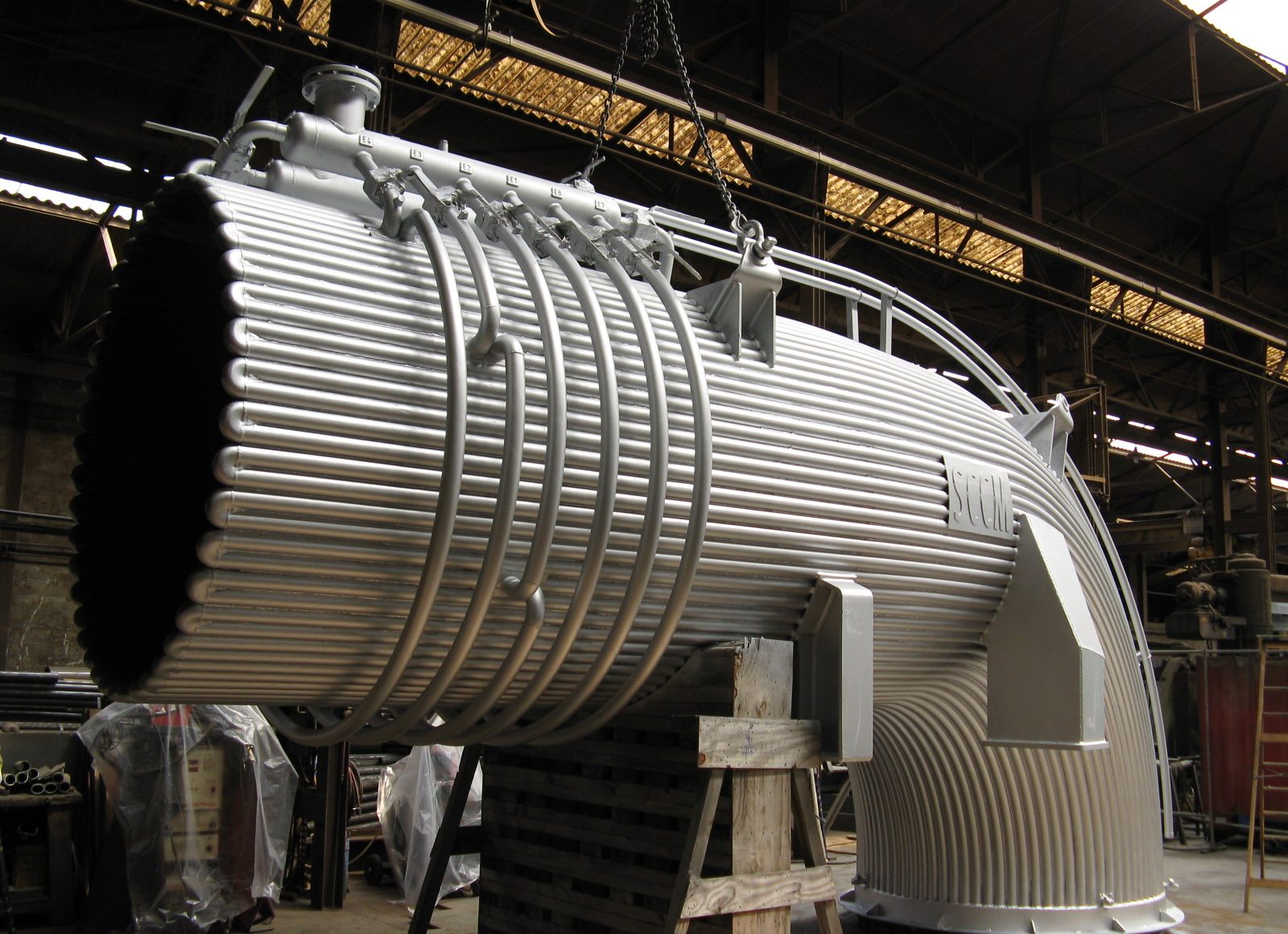

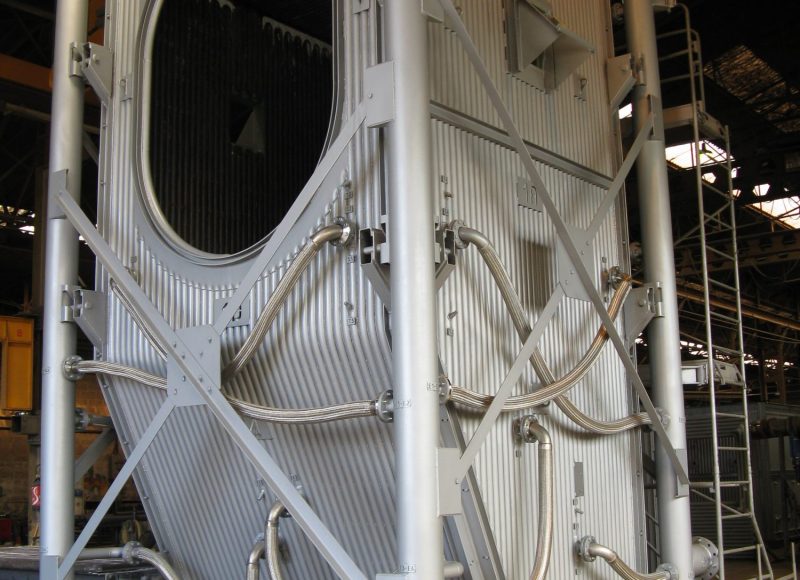

- Water-cooled steel and copper panels for furnace

- EAF water-cooled panels

- Water-cooled panels for EAF / LF oven

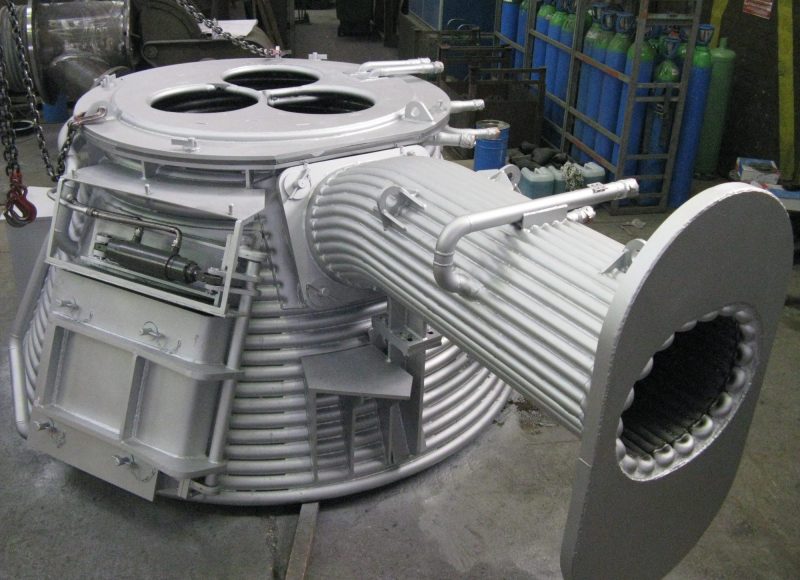

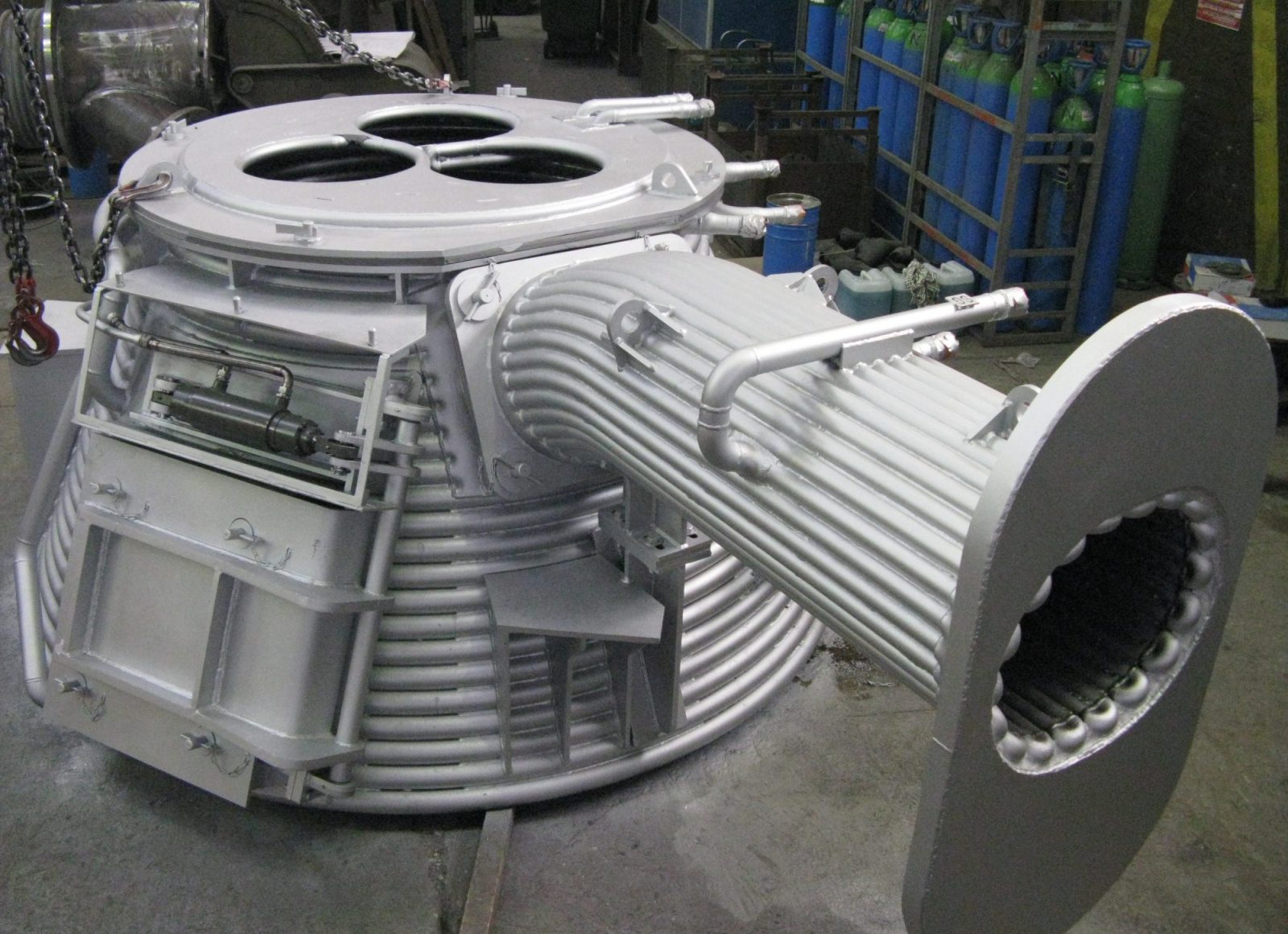

- AOD water-cooled converter hood

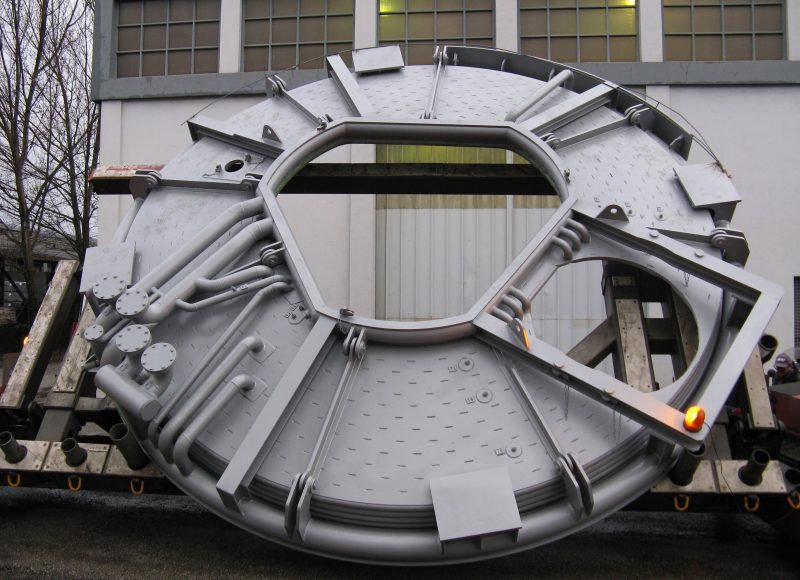

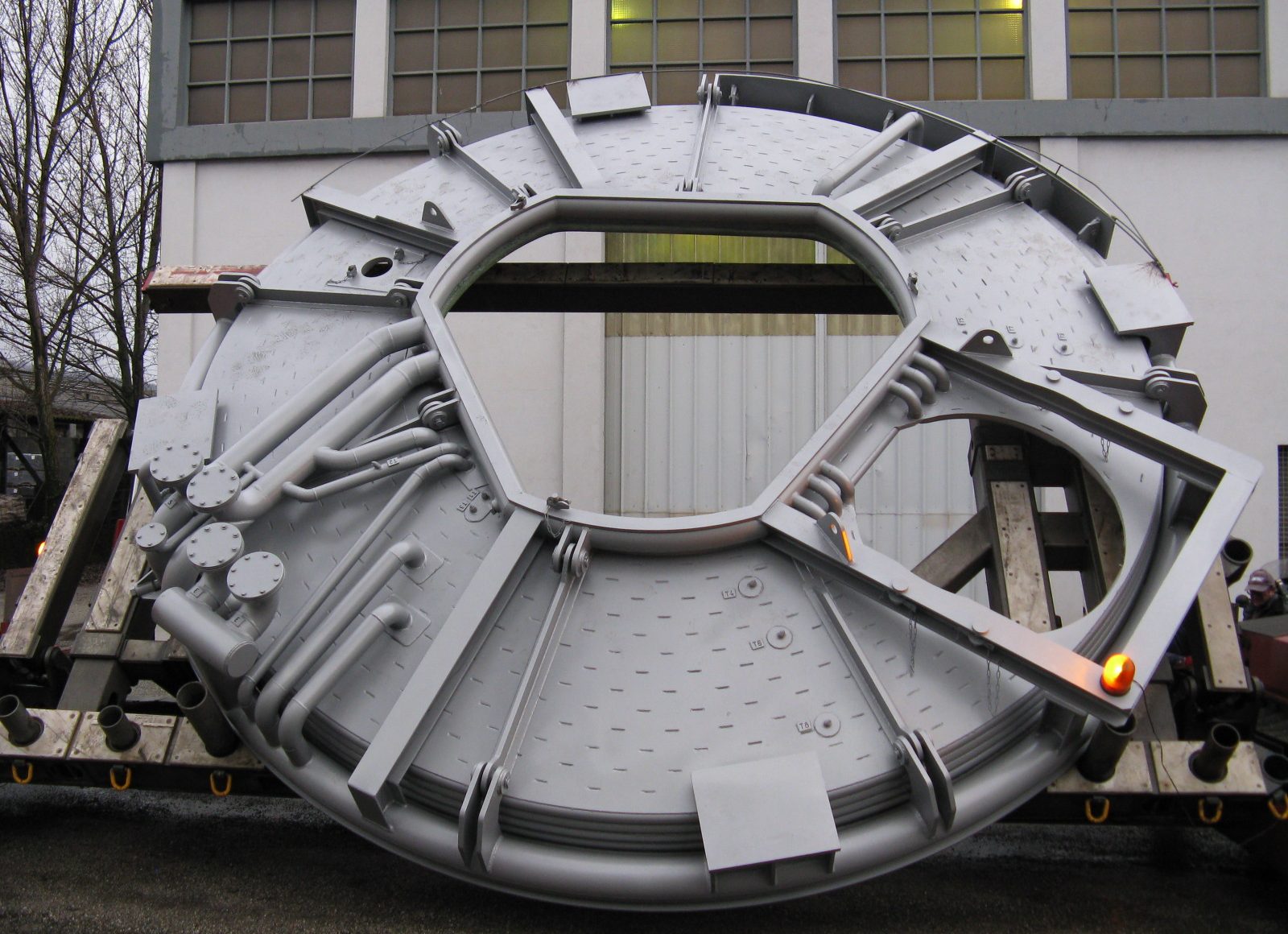

- Complete water-cooled vault

- Water-cooled afterburner chamber (Case study)

Gallery of 7 photos