Issue:

A steel mill called on us to make the post-combustion chamber of their 160-tonne direct current furnace more reliable and to reduce the cost of using it. The production losses due to the high frequency of maintenance shutdowns were too high a cost. Their problems were:

A steel mill called on us to make the post-combustion chamber of their 160-tonne direct current furnace more reliable and to reduce the cost of using it. The production losses due to the high frequency of maintenance shutdowns were too high a cost. Their problems were:

- Corrosion in the lower part by condensation of corrosive elements on the surface of the pipes during transient phases.

- High local thermal loads (around 400kW/m2)

- Normal general wear and tear by erosion

- High maintenance costs: limited lifetime of the part + long intervention time for panel changes

- Water flow distribution not adapted to the thermal loads of the room

Suggested solutions:

- Diagnosis of the existing system: Delta Water measurement campaign and water pressures in order to map thermal loads and water supply conditions.

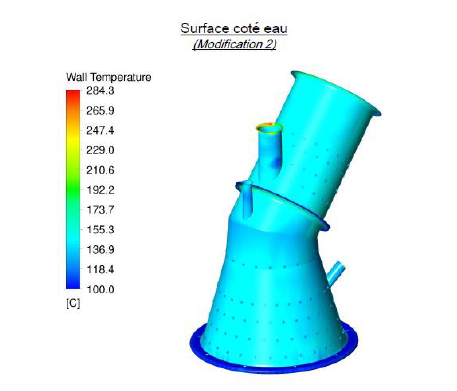

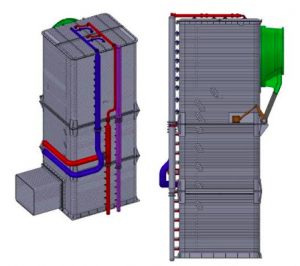

- Adapted design: thermal and hydraulic studies (SolidWorks software), increase in volume (+40%), new post-combustion chamber made up of 3 superimposable monobloc elements allowing easy assembly/disassembly. All circuits equipped with PT100 probes with connection box.

- Complete supply of the post-combustion chamber with access gangways: adjusted manufacturing, passage to the test bench in our facilities.

- Follow-up after commissioning: use of temperature recordings and test bench passage to check the reliability of the equipment.

Noted improvements:

- Simplification of assembly operations

- Much easier to carry out maintenance operations

- Very sharp reduction in power trips on the furnace; previously due to alarms on water temperatures at the outlet of circuits

- Better consideration of thermal loads

- Significant reduction in downtime

The main characteristics are:

- Parallelepiped shape with a hopper

- Swivel sleeve

- Two “pre-quench” water injection canes on the upper part of the machine

- Afterburner volume of 144m3

- Dimensions: depth 2768mm x width 4530mm x height 11462mm (excluding hopper)

THIS NEWS MAY ALSO INTEREST YOU:

04.09.2023

SCCM ALP carries out thermofluidic and thermomechanical numerical simulation to validate the behaviour of critical parts in cooled elements.

Read more