SCCM ALP designs installations and equipment for the capture/cooling of fumes and dust generated by steel melting, conversion and refining processes.

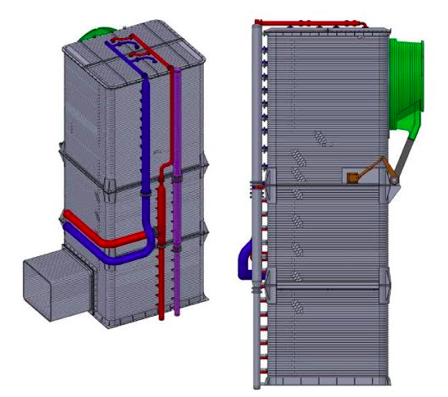

Post Combustion Chamber

The post-combustion chambre ensures the heat treatment of the fumes captured on the arc furnace by oxidation of the combustible fraction of these fumes (CO and H2).

In addition to this primary function, the post-combustion chambre collects part of the dust in the lower part, at the level of a hopper or sedimentation chambre.

In the principle and to guarantee the efficiency of the afterburning of the unburnt material, it is necessary to be able to guarantee :

- Sufficient turbulence to ensure an intimate mixing of the unburnt material with the combustion air.

- A minimum temperature in the range of 850-900°C

- Sufficient residence time to ensure complete combustion

In addition, the quantity of air introduced for combustion must be sufficient to guarantee a minimum oxygen level of 6% at the outlet of the afterburner chambre.

The high-temperature and highly turbulent reactive flow necessarily generates significant thermal loads which must be taken into account in the design.

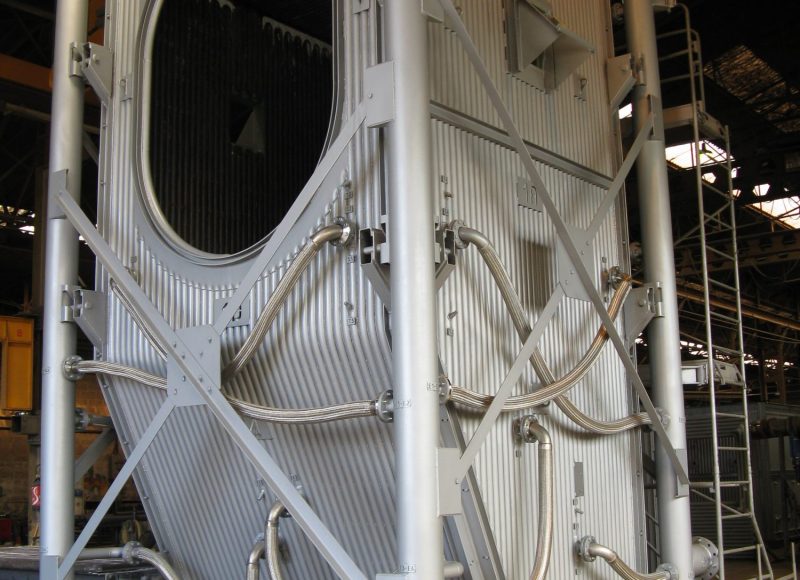

Water-cooled pipe

These elements are associated with the installations for collecting and dedusting steel production tools: arc furnace, ladle furnace, AOD, etc.

The geometry, dimensioning and design of these cooled tubular ducts are adapted according to the destination tool and the installation and operating constraints:

- Fixed or mobile ducts

- Design with optimized aeraulics to limit erosion and dust deposition phenomena

- Circular, rectangular section, etc.

- Change of section and direction

- Pipe diameter and thickness depending on the intensity and combination of stresses: thermal load, erosion, corrosion

- Definition of water circuits (number and length of circuits) adapted to the distribution of the thermal load

- Consideration of the water flows and pressures available on site

- Preventive surface treatment: Inconel arc-spray, Inconel hard facing, tungsten carbide hot spraying, etc.