High temperature waste incinerators and high-temperature sludge treatment (850 to 1000°C) produce concentrated flue gases that are highly charged with Sulphur Oxides (SOx), Chloric Acids (HCL), Hydrofluoric Acids (HF), Dioxins/Furans (PCDD/PCDF) and Heavy Metals. We therefore offer injection of several reagents, in powder form, according to our customer’s needs in order to eliminate, by agglomerating to these pollutants. This treatment method can be applied to other areas than waste incinerators.

SCCM ALP by its history, ALP PROCESS is a reference for the number of smoke treatments. They are referenced by the world leaders in smoke treatment.

Treatment of Sulphur Oxides (SO2 and SO3) and Hydrochloric (HCL) and Hydrofluoric (HF) Acids

In order to reduce the level of sulphur oxides, hydrochloric and hydrofluoric acids we inject powdered reagents into the flue gas ducts upstream of the bag filter. We can use several products:

- Sodium bicarbonate (NaHCO3) is more efficient on sulphur oxides

- Slaked lime (Ca(HO)3) is more suitable for hydrochloric acids

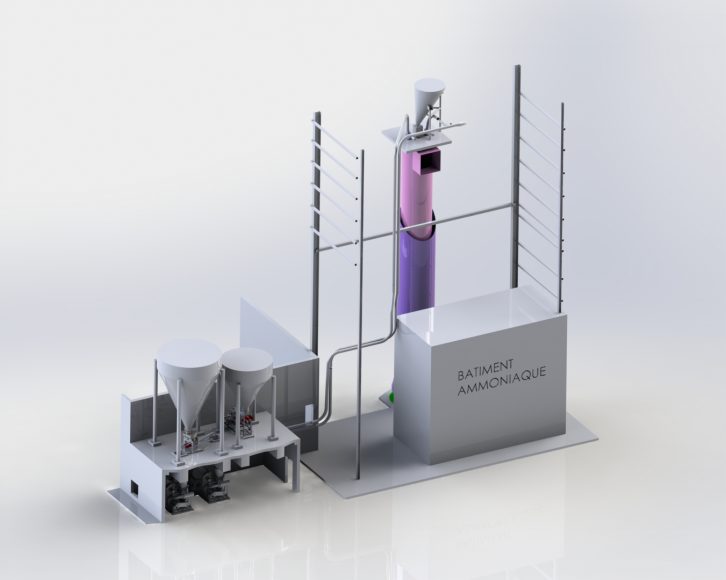

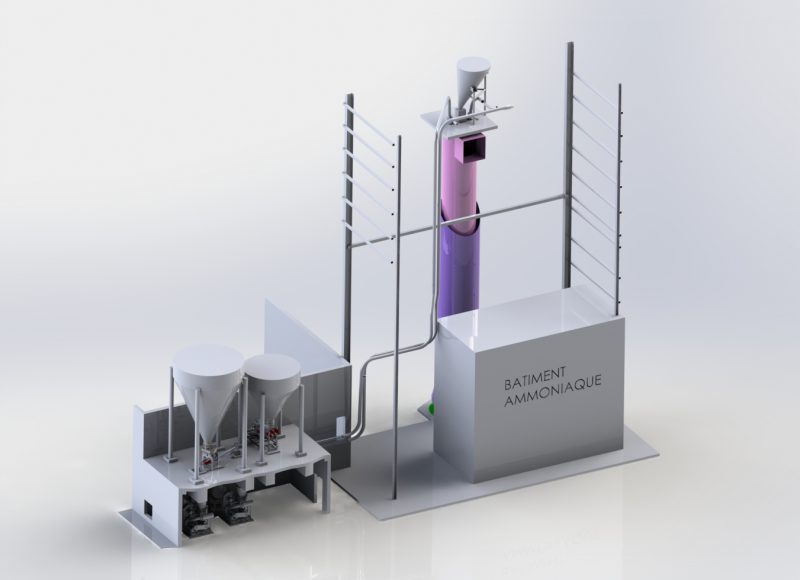

We propose complete sets :

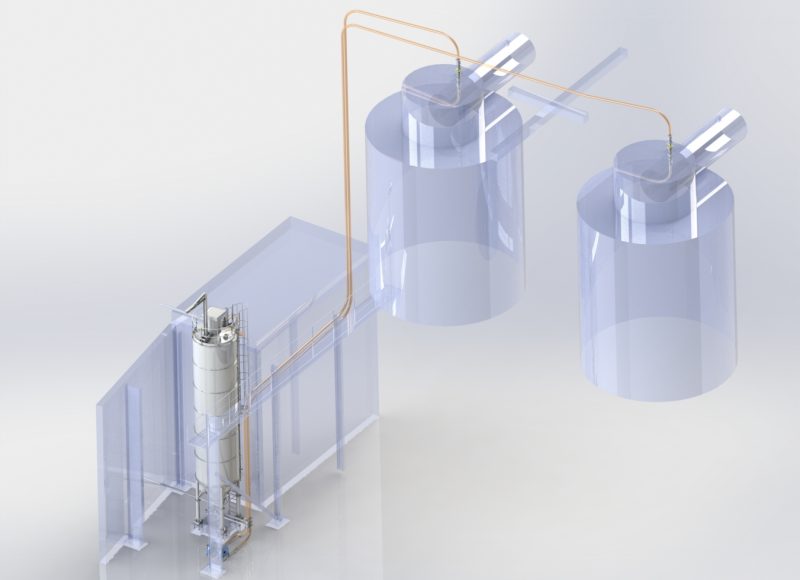

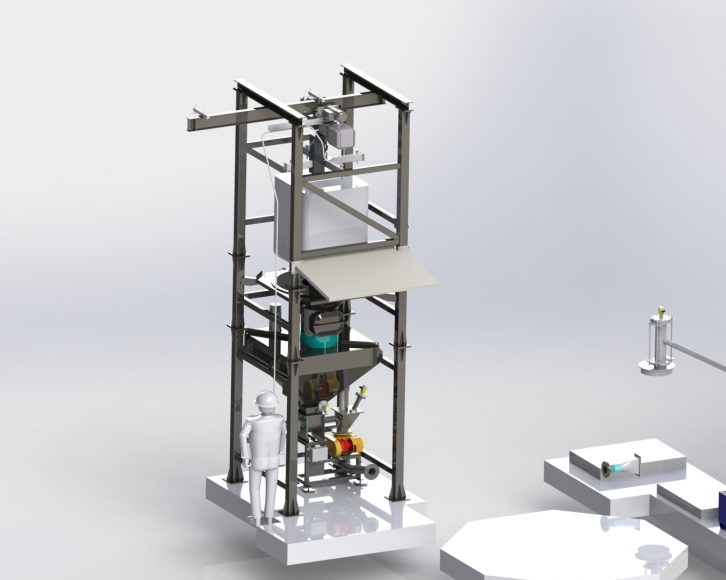

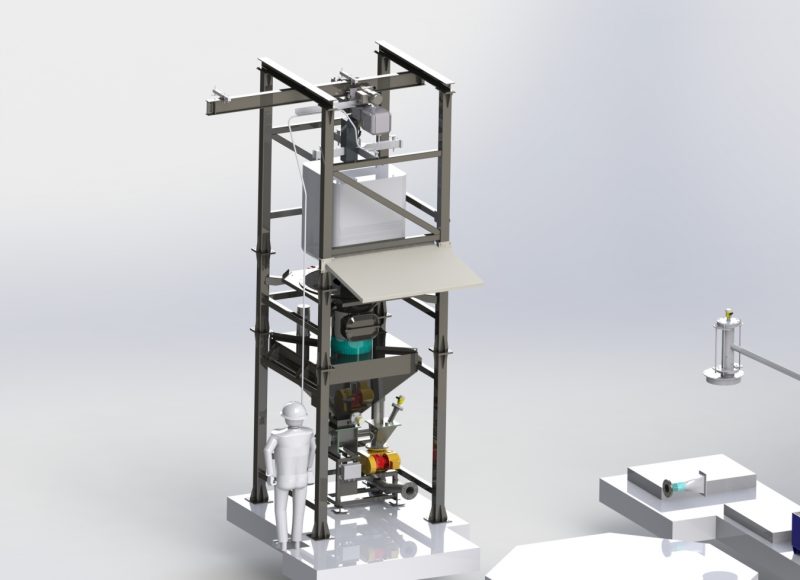

- Storage (Silo or Big Bag)

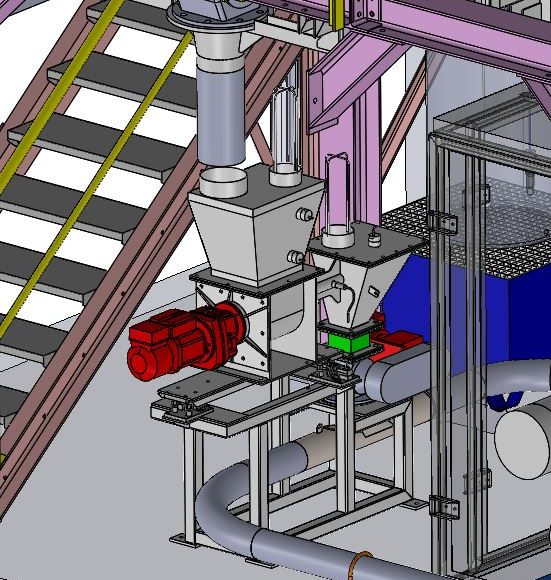

- Extractor (devourer)

- Grinding

- Dosing (Spiral or auger)

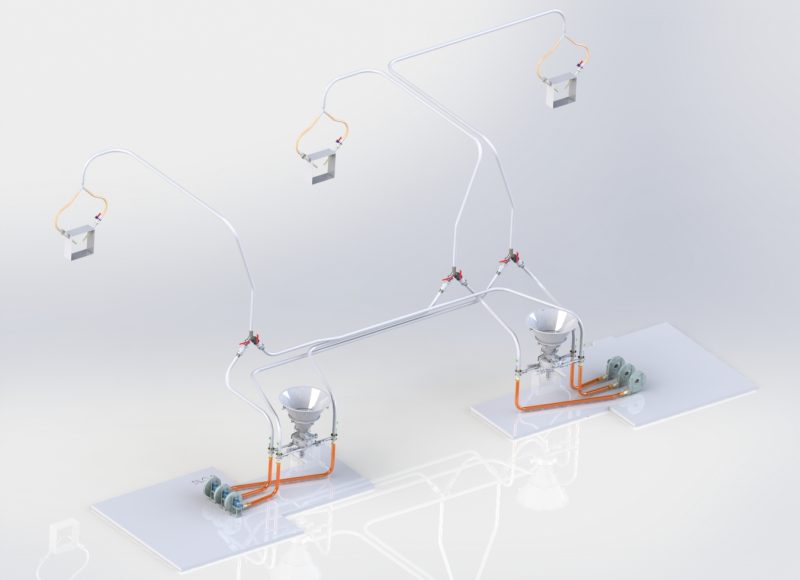

- Pneumatic transport and injection directly into ducts thanks to our injectors

A flow range from 0.05 m3/h up to 12 m3/h with precise dosing. Possibility to feed up to 4 lines with a single silo. Dosage regulation is based on the data received from the fume analyzer. This system can be installed on a new treatment or as a complement to an existing treatment that no longer meets the standards or is subject to pollution peaks.

Grinding

When using sodium bicarbonate (NaHCO3), the particle size must be taken into account. Indeed, the finer the product, the better its efficiency on pollutants. Our company offers industrial grinders designed by the company OFFICINA 2000, of which we are the official reseller for France, specialising in the grinding of sodium bicarbonate. We have two types of mills, compact grinder and selector grinder.

Compact grinder allows to have :

- Small flow rates

- Reduced space requirements

Selector grinder allows :

- Regulate the granulometry

- Achieving very fine grain sizes

The grinding unit is equipped with a metering screw and a transport fan, which allows having a common unit in a small space. Our grinders are mounted with a pneumatic injection system of glycol, an additive that eliminates clogging of the product. We also offer soundproofing boxes to reduce the noise level of the grinder.

TEST IT: If you wish to test the sodium bicarbonate we can offer you a complete dosing and grinding stand for rent.

Treatment of dioxins/furans and heavy metals

In addition to acids and sulphur oxides, we also find dioxins/furans (PCDD/PCDF) and heavy metals in the flue gases from incinerators. For this, several reagents can be used in addition to Sodium Bicarbonate and Lime:

Activated Carbon

- Lignite Coke

- Natural Mineral Substance (Minsorb, Dioxorb…)

We offer complete sets:

- Storage (Silo or Big Bag)

- Extractor (devourer)

- Grinding

- Dosing (Spiral or auger)

- Pneumatic transport and injection directly into ducts thanks to our injectors

- Gravity injection

As the quantity to be injected is much smaller than bicarbonate or Lime, SCCM ALP propose several microdosers with flow rates ranging from 0.002 m3/h to 1 m3/h. In some applications the demand for SOx, HCL and HF lowering is low which allows us to propose the mixture of Lime and Minsorb in order to avoid having two sets of reagent injection.