The dosing of powders is an essential operation in the manufacturing process. If the dosage is not carried out correctly, the quality of the finished product will be affected, and it must therefore be very precise. In the management of powders, several processes make it possible to guarantee the exact dosage of each component:

- Powder dosing (dosing station)

- The micro-doser

- Dosing by transfer screw

Dosing stations

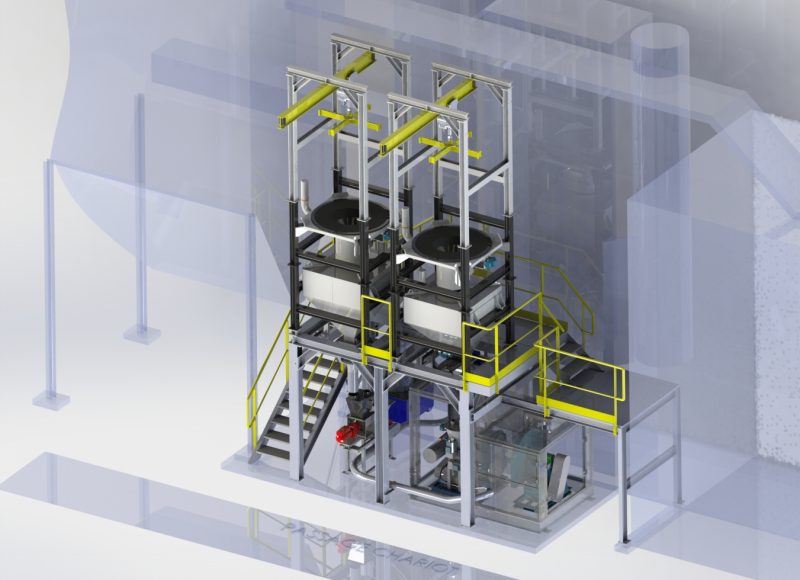

Let’s take the concrete application of our customer, a concrete manufacturer who is looking for a fine and automated dosing of several pigments for the colouring of its concretes.

After checking the manufacturing process and the installations, we identified a lack of precision in the manual dosing. We proposed an automated solution for the routing of the various powders by mechanical transfer – weighing – dosing and transfer of the resulting mixture with the installation of :

- A set of reception hoppers equipped with a filter with a cleaning system

This dosing station system is equipped with :

- 1 to 5 independent vibratory systems for conveying

- A weighed hopper

- A pneumatically evacuated shipping SAS

This new device has enabled the company to increase its productivity and the reliability of its product.

Micro-doser

The micro-doser is a dosing device adapted to the dosing of micro-particles. These volumetric dosers are equipped with :

- A dosing screw (sized according to the flow rate)

- An integrated emulsifier (geared motor)

- A buffer hopper (with level sensors)

- As an option, a honeycomb SAS can be installed to connect the micro-doser to a pneumatic transport line

Transfer screws

Finally, transfer screws are designed for large dosing volumes and can be used to transfer all types of products (abrasive, finer granulometry, etc.) in incineration plants, cement plants and many others. They can also be used in the pharmaceutical sector. There are several types of transfer screw:

- Worm screw

- Screw with or without core

- Screw with or without bearing

These can be manufactured and designed in stainless steel or steel according to the company’s requirements. They can be available in food grade finish and ATEX version.

SCCM ALP offers these dosing devices but also their dimensioning by calculation according to your process (flow rate, particle size, transfer length, …)