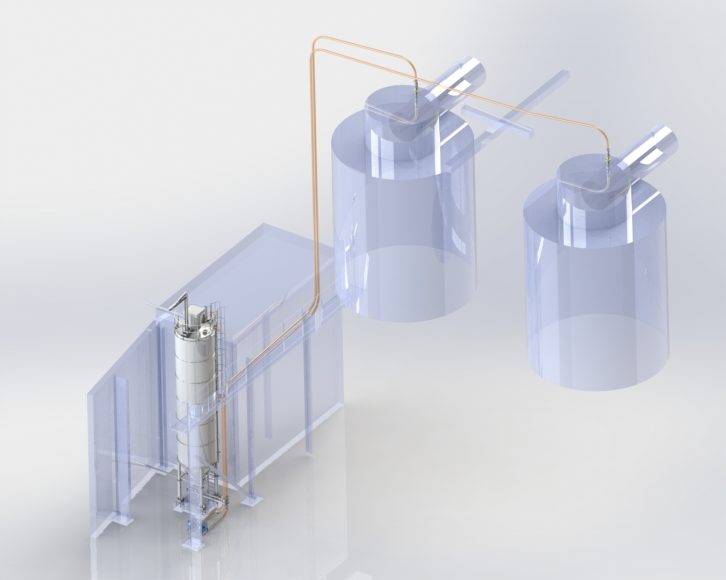

Moving material from one point to another is a very frequent problematic for many industrial processes. SCCM ALP provides different solutions to answer customer demand whatever the type of product to be transported, in particular pneumatic or bulk transport.

Pneumatic Transport

Pneumatic conveying has the advantage of great flexibility in the routing of pipelines. As it is completely sealed, it brings cleanliness to the powder transport process and is the only process that allows powder transport in a confined space.

There are 2 main principles of pneumatic transport:

- Pneumatic transport in diluted phase called low pressure

- Pneumatic transport in dense phase called high pressure

Dilute-phase transport

Air is the mean of particles transportation, which means a very high pipe speed and the use of a large quantity of air in relation to the material. Here are its assets:

- Relatively high product transport speed

- Suitable for short distances and flow rates.

- Multi-product transport

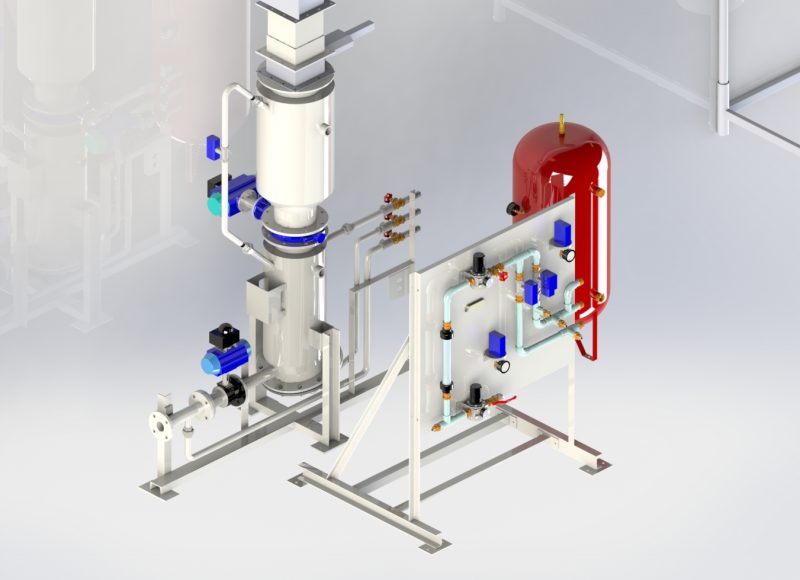

Dense-phase transport

The amount of air is much lower compared to the diluted phase. The product advances in plugs and the conveying speed is relatively low. The air pressures used are much higher and this technic is only applicable to fluidizable products or products with a very similar grain size.

This method is suitable for products to be conveyed over long distances. There are also a reduction of abrasion and friction phenomena.

Addressed application :

Cement works, iron and steel industry, food industry, concrete plant, smoke treatment.

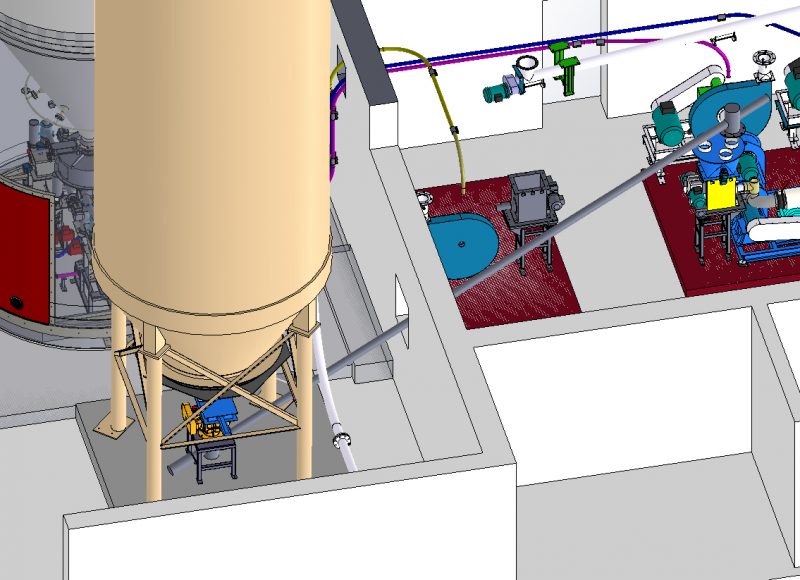

Bulk Transport

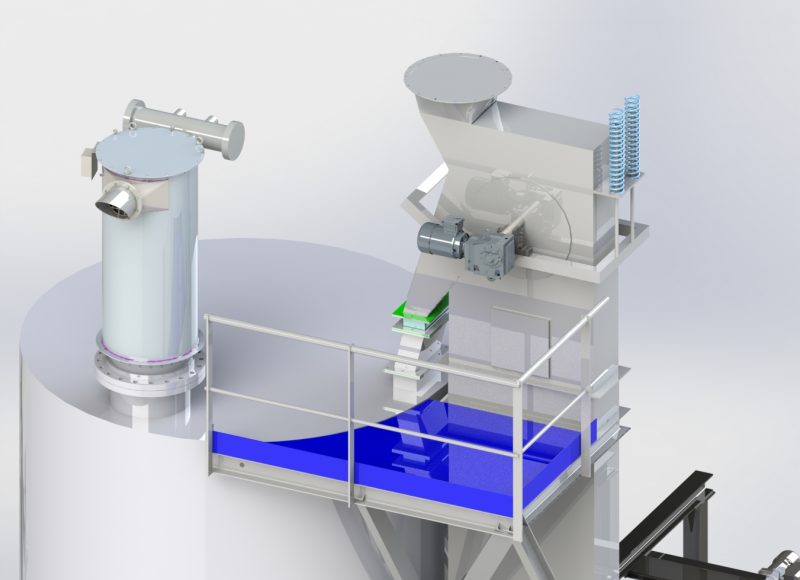

SCCM ALP offers various solutions to convey bulk material to any container, whether it is a silo, hopper, big bag….

The issues guiding the technological choice are the distance, the flow rate and the particle size.

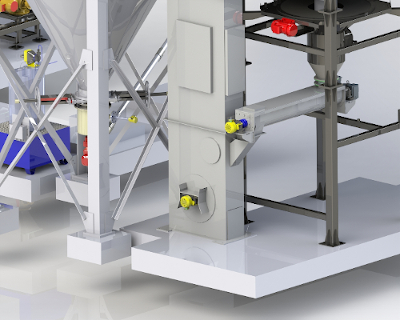

Transfert screw

Transfer screw conveying solutions :

- Short distance

- High throughput

Equipment intended for large dosing volumes but also used for product transfer. Also allowing transferring all types of products (abrasive, small granulometry…), with different designs:

- Worm screw with or without core

- Screws with or without bearing, depending on the function and the product

Manufactured in stainless steel or carbon steel, the transfer screws can be equipped with one or more inlets and outlets to meet your needs. Also available in food quality finish, in ATEX version, the screws are adapted according to the constraints that are imposed.

Bucket Elevator

Typically used for vertical product transfer, bucket elevators are an ideal mean of transport for filling silos or containers located high up.

Its flexibility allows, thanks to different bucket designs and sizes, to transfer products with granulometry ranging from powder up to 50mm, food or non-food, up to a height of 60m.

Addressed application :

Cement works, iron and steel industry, food industry, concrete plant, smoke treatment, etc…