SCCM ALP specializes in the management of the storage of all types of solid particles in silos or big bags. From this experience, it has developed a specific knowledge for waste incinerators.

Thus, SCCM ALP is the official french distributor of german manufacturer STANELLE for France since several years.

How to choose your storage method?

Storage by big bag is the simplest to implement but its main drawback is its reduced volume, which limits it in the process. The silo does not have this limitation, but it can present space constraints. Beyond the storage means itself, SCCM ALP proposes the solution best adapted to the physical characteristics (hardness, granulometry…etc…) of the stored particles (mechanical or pneumatic means of transfer, means of deburring and cleaning, insulation by valves, sealing of the process towards the outside by overpressure or vacuum etc…).

Silo and big bag unloading for industries

SCCM ALP offers several types of unloading:

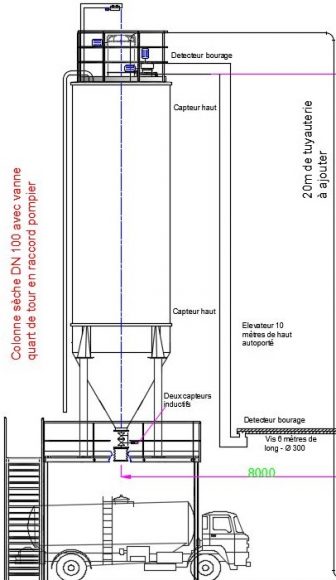

- Silo unloading by loading handle for tanker trucks

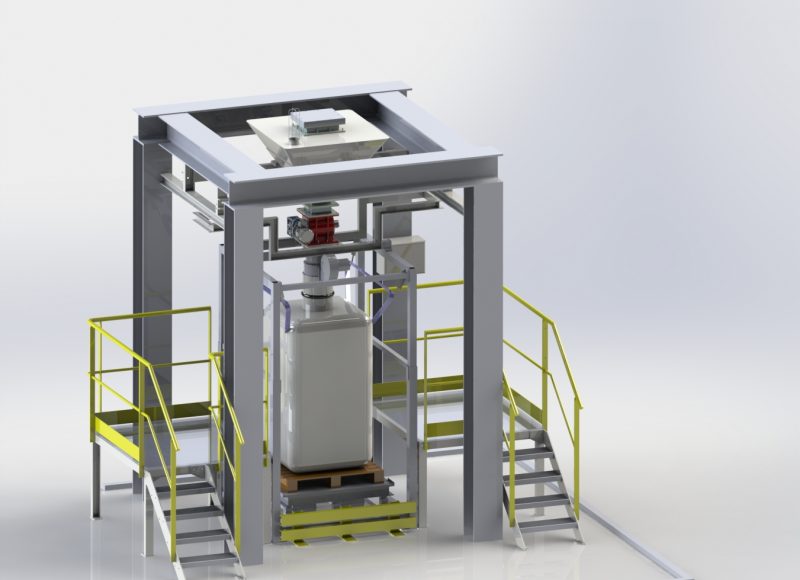

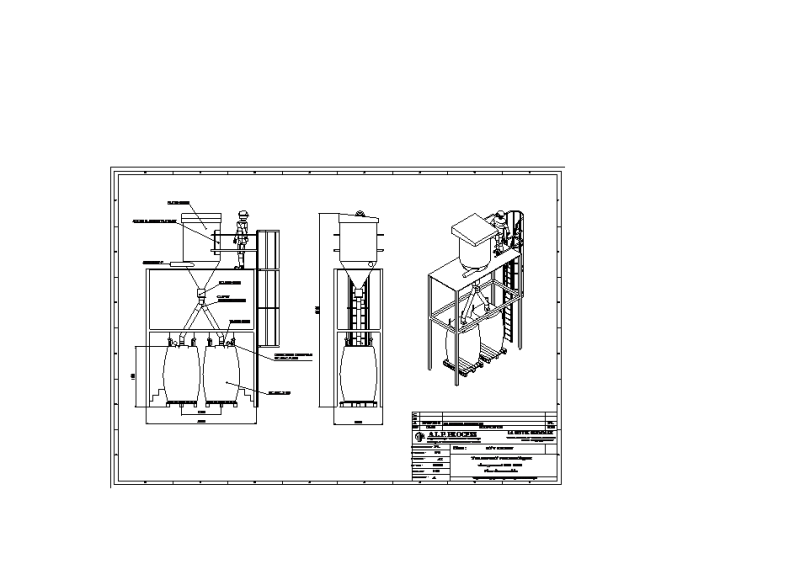

- Unloading by big bag station

SCCM ALP offers solutions for the recovery of waste resulting from the combustion of a furnace, under an electrofilter, itself under a filter for recycling. The recovery in a big bag by gravity or by an SAS of transport towards a silo is done in order to be transferred in a truck (loading handle).

SCCM ALP intervenes for all storage and transport problems, whether upstream or downstream of the flue gas treatment process and the recovery of waste from the combustion of household waste (MWIP). We are also involved with water purification sludge systems which can present dangers for the environment and which must be treated downstream in the recycling process.

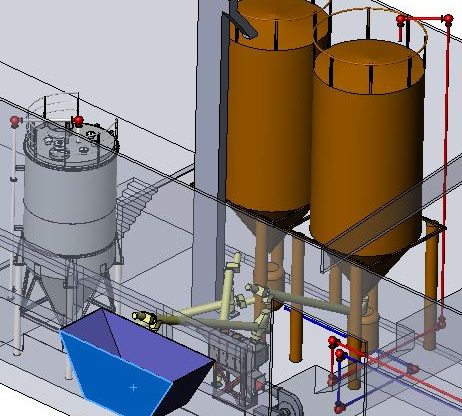

For the recovery of waste under a filter or under an electrofilter, silo storage involves pneumatic transport and a loading sleeve underneath for the transfer of the waste by lorry.

Storage in a Big Bag

Our big bag unloaders are designed according to our customers’ specifications and adapt to all their storage and installation problems before transfer to their process. Big bag unloading can be done either by a hoist (Atex or not) or directly by a spreader. In the lower part, our unloaders can receive a micro-doser in the case of activated carbon or directly a transfer screw.

Our engineering and design department is able to handle all the metal structures that may be involved in the problem of an installation.

Storage in a silo

Our silos meet every customer demand, whether for powder reagents such as lime, activated carbon, sodium bicarbonate or other bulk products such as sand or corrosive. We are able to find solutions for your processes and for all your treatments.

Their manufacture is adapted to the needs of our customers and can be postponed according to the projects. Whether they are made of steel, stainless steel or composite materials, they can be positioned either on the ground on a frame or a supporting skirt to integrate a confined space (easier for ATEX zone) or be integrated in a closed building. They can also be integrated with a weighing chain for a better consumption in the process and can also meet ATEX standards.

The standard equipment of our filters are a de-clogging filter, a safety valve, an internal access hatch, 2 level detectors (top and bottom) and a safety barrier on the top. On the lower part a 60° cone with a flange, a frame positioned on 4 feet, a filling pipe and an access ladder to the upper part.