The electric arc furnace is a strategic tool in the melting process of steel from the recycling industry. Steel manufacturers turn to SCCM ALP in the permanent search for increased productivity but also for safety and durability over time for the equipment that makes it up (e.g. top of the vessel, vault and all tubular elements cooled with water).

Vessel Top

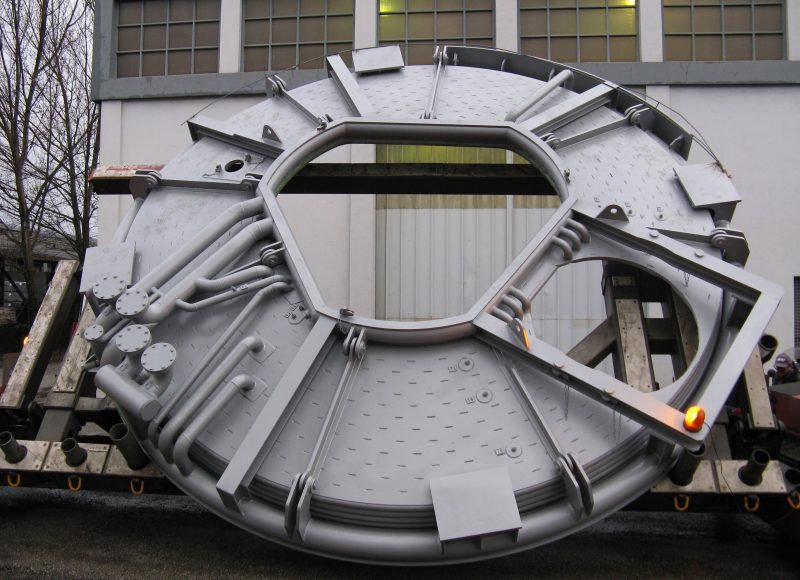

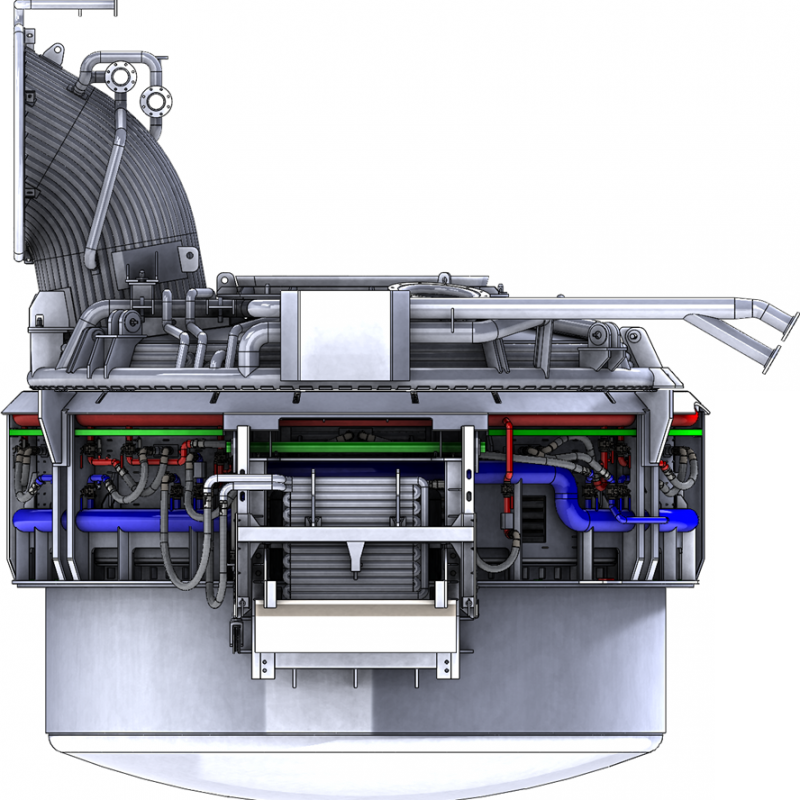

An electric arc furnace top vessel consists of 2 main parts:

- A steel vessel bottom lined with refractory material.

- The top of the tank equipped with tubular water-cooled panels

The top wall of the tank is equipped with a door for deslagging operations and openings for the passage of oxygen lances, oxyfuel burners or coal lances.

The design of a tank top must take into account :

- The geometrical constraints for the installation of this auxiliary equipment.

- The multiple stresses to which the cooled elements are exposed (high thermal loads, mechanical shocks with scrap metal, etc.).

- The safety of use, maintenance and replacement operations of the water-cooled panels

Water-cooled vault

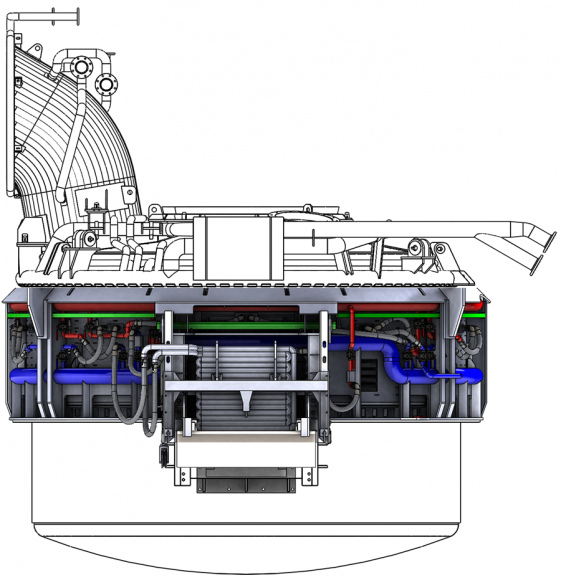

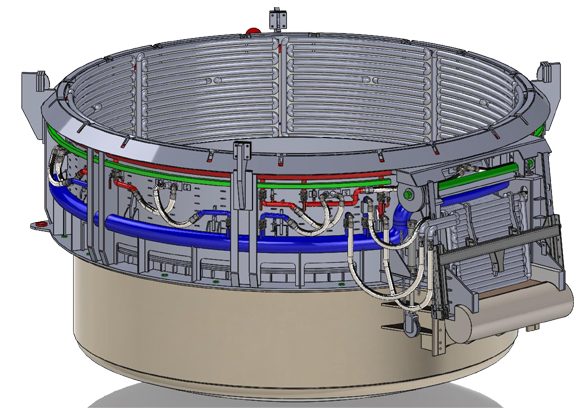

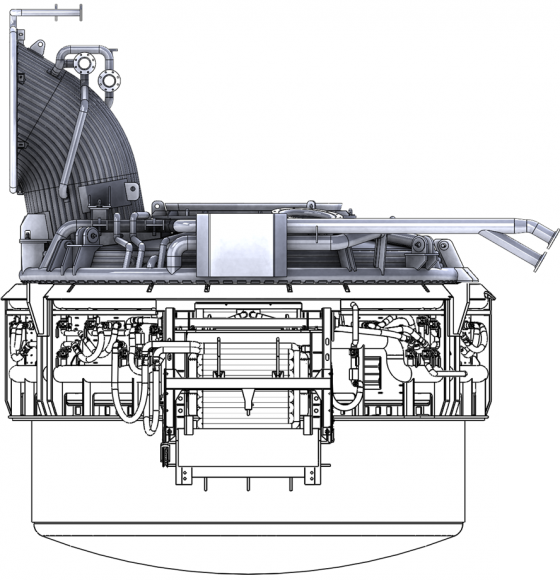

A water–cooled arc furnace vault consists of two main subassemblies:

- A one-piece tubular screen or a set of water-cooled panels.

- A structure ensuring the functions of water supply and support of the water-cooled panels and accessories

The vault is also equipped with an opening to receive :

- A vault door and vault in the central part for the passage of the electrodes

- A water-cooled tubular elbow for the capture of fumes

- Miscellaneous accessories (water-cooled launders, pressure tap, etc.)

The design of a vault must take into account :

- The geometrical constraints for the installation of this auxiliary equipment.

- The multiple stresses to which the cooled elements are exposed (high thermal loads, mechanical shocks with scrap metal, etc.).

- The safety of use, maintenance and replacement operations of the water-cooled panels

Water-cooled vault elbow

The elbow on vault is the first cooled fume collection element placed on an electric arc furnace. Given the high temperatures and the quantities of dust collected, the elbow on the roof is therefore exposed to very high stresses: erosion and thermal load.

This is composed of :

- A tubular casing

- A tubular screen at its outlet for the furnace tilts on the deslagging and casting sides

The design of an elbow on vault must take into account :

- The geometrical constraints for the installation of this auxiliary equipment…

- High levels of stress both in terms of erosion and thermal loading

- The distribution of the thermal loads between the lower and upper surfaces

- Deposit risks

SCCM ALP integrates in its process

- Thermal and hydraulic studies taking into account the parameters measured on site

- The study or adaptation of the hydraulic circuits that supply water to cooled appliances

- A 3D design with the establishment of the complete plans of the devices

- Quality manufacturing with qualified operating procedures and specific assembly methods

- Verification of hydraulic parameters after manufacture on a SCCM ALP test bench

- Commissioning assistance with verification of operating parameters

- A follow-up of the installed devices