The functions of these tools are the conversion of pig iron from blast furnaces or the conversion and refining of crude steel from arc furnaces. SCCM ALP designs the containment and capture equipment placed above the load to be treated:

- BOF (Basic Oxygen Furnace), AOD (Argon Oxygen Decarburization) converter hoods

- Lids/vaults of ladle furnace, VOD (Vacuum Oxygen Decarburization), VIM (Induced Vacuum Melting)

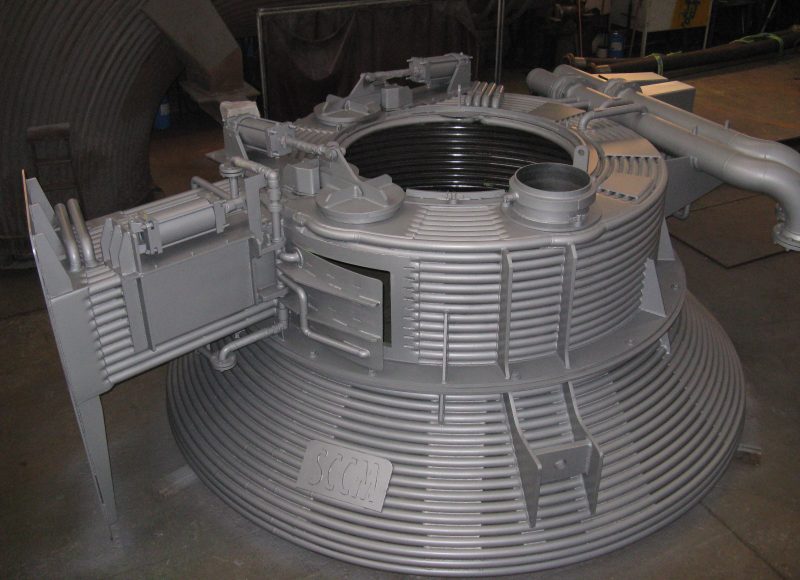

Lids and vaults

The lid or vault of the ladle furnace is placed just above the ladle containing the charge to be treated and it ensures the capture of the fumes generated during the refining process.

The design of this vault must take into account :

- The geometrical layout constraints of this auxiliary equipment (oxygen lance, sample taking, additions feed chutes, lined wire passage, etc.).

- The multiple stresses to which the cooled elements are exposed (high thermal loads, erosion-corrosion phenomena, etc.).

- Reliability and safety of use

- Maintenability

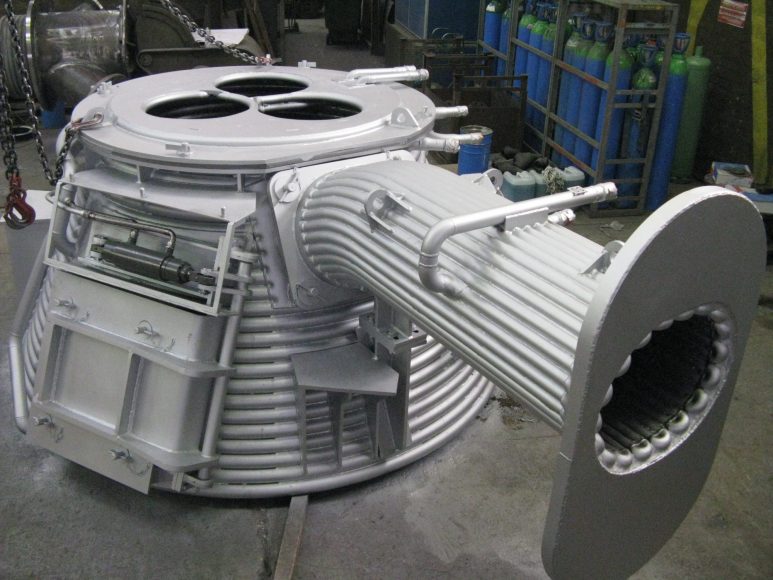

Converter hood

The converter hood is placed just above the converter or retort containing the feedstock to be treated and it ensures the capture of the fumes generated by the process.

The design of a converter hood must take into account :

- The geometrical constraints for the installation of this auxiliary equipment (oxygen lance, sampling, additions feed chutes)

- The multiple stresses to which the cooled elements are exposed (very high thermal loads, erosion-corrosion phenomena, etc.)

- Reliability and safety of use