Increasing the lifting capacity and safety of overhead cranes is a major concern of the steel industry. In order to combine productivity and safety.

In addition to conventional solutions for replacing or upgrading cranes, it is often possible to lighten the equipment placed between the crane and the load itself:

- Ladles

- Intermediate spreaders

- Clevises

- Steel or titanium lamellar hooks

By using the optimisation made possible by finite element calculations, it is possible to considerably lighten these elements, while improving their safety of use and their service life.

SCCM ALP offers you the study of technical improvement as well as manufacturing, but also the economic study of return on investment and amortization of the device over time.

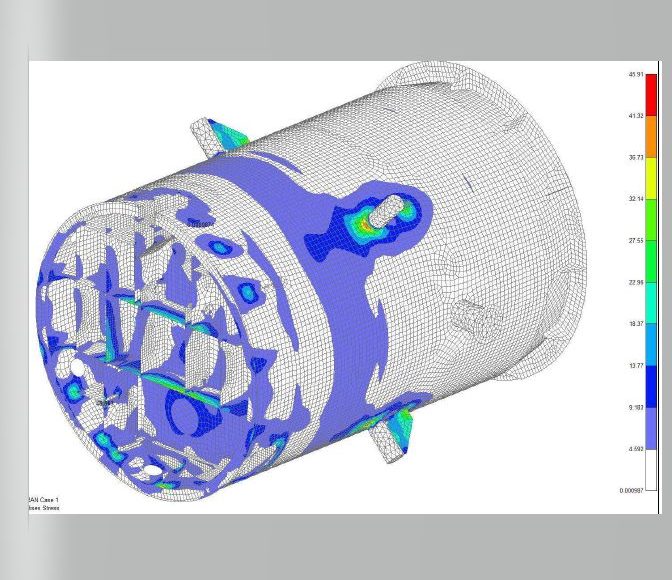

Casting ladles

Essential elements of transport containing liquid steel, they can be of different shapes. By optimising their weight, the payload transported can be increased.

- 3D CREO modeling

- Finite element calculations and ANSYS STRUCTURAL post-processing according to the different loading cases (taking into account temperatures)

Lamellar hooks

Essential elements in the transport of ladles, the optimization of their weight allows to increase the transported payload, and thus productivity gains.

- 3D modelling CREO

- Finite element calculations and ANSYS STRUCTURAL post-processing according to the different load cases

- Drafting of an operating and maintenance manual