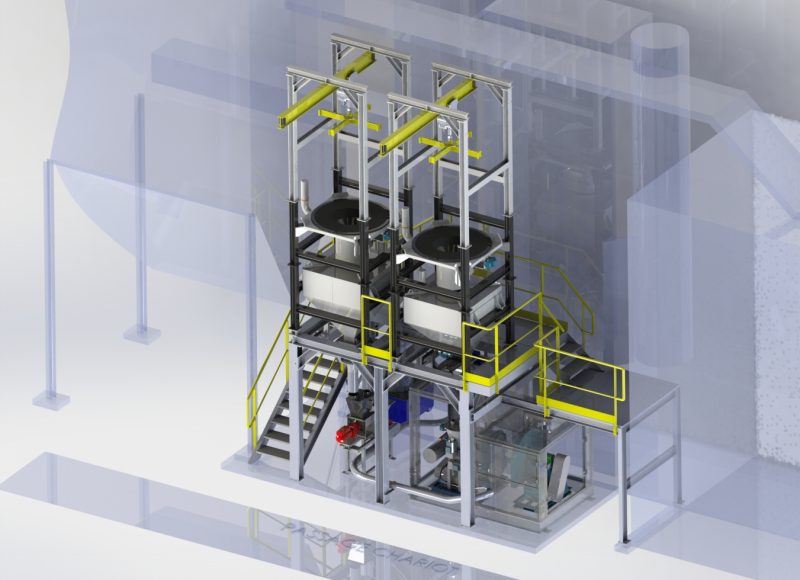

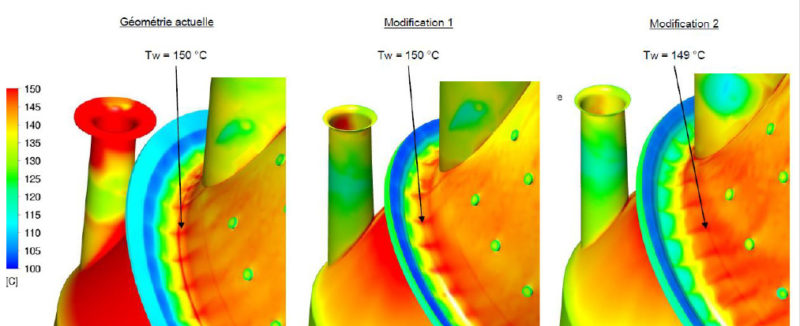

Safeguarding processes, preventing breakdowns and minimizing production stoppages remain fundamental to a healthy steel industry. At the request of one of our customers, SCCM ALP applied its expertise as a manufacturer of flue gas treatment systems to the finite element modeling of the converter hoods and double-walled main flue of its flue gas cooling system.

This modeling enables our design office to anticipate the thermomechanical behavior of tools in the various stages of operation, under constraints of temperature and fluid circulation (water and fumes). It validates field observations and enables the modification of drawings for critical parts. This will make manufacturing all the more sustainable!

Finite element modeling: what’s it all about?

To determine the thermomechanical behavior of equipment under fluid pressure and temperature, finite element modeling uses a set of numerical techniques to solve a certain class of physical problems, based on partial differential equations whose exact solutions are generally not known. The product is modeled by a mesh based on two geometric objects:

– Simple shapes: volume, surface, line.

– Special points: knots.

SCCM ALP’s in-house design office uses ANSYS software for this purpose.

Modeling thus makes it possible to subject each of these shapes and points to particular forces, and thus to zone exactly where the elasticity of the steel or the post-treatment of welds, for example, may pose a problem: rapid wear, corrosion, erosion…

At SCCM ALP, our experience as a designer-manufacturer means that we know our customers’ mechanical parts and processes inside out, but our design office needs a supercomputer to model a part in operation. These thermodynamic finite element modeling calculations require enormous numerical capacity.

The power of modeling is explained by the multiphysical complexity of installations:

- Plant size

- Reactive flow on the flue gas side (combustion and exchange by forced convection and radiation)

- Two-phase flow on the water side

- Thermomechanical behavior of the interface between the 2 fluids (double wall or tubular wall).

An innovation that will ensure the long-term future of the production process

And therefore the lifespan of equipment, thereby increasing its profitability…

Everyone is aware of the financial and human cost of maintenance and production stoppages, in all industries but especially in the steel industry.

Knowing the weaknesses of your installation allows you to anticipate corrective actions and schedule their implementation, thereby minimising their consequences.

SCCM ALP’s support from start to finish

Our integrated design office and manufacturing workshop enable us to support you throughout your technical audit:

· Collecting and characterising the data needed for modelling: equipment material, manufacture, assembly, analysis of fluids (smoke, water) and their circulation, etc.

· Modelling of equipment and fluids using our expertise as a designer-manufacturer and our ANSYS software

· Thermomechanical and thermofluidic simulation using a supercomputer

· Redesign of manufacturing drawings

· Manufacturing your critical parts

· Livraison, installation et mise en service.

More information ? Contact us !