Existing situation:

An EAF plant contacted us to change their ladle furnace cover. This upper part of the ladle contains the slag load to be treated. It captures the fumes generated during the refining process and allows them to be treated and discharged without danger. It is a complex part due to its technical nature, geometric constraints of the auxiliary equipment, erosion and corrosion phenomena, etc.

Customer issue:

The steel mill teams wanted a new cover that would be less expensive in terms of maintenance. The current one required a change of the roof (refractory material) every 60 casts (approximately). This caused many production stoppages and lost time for steelmaking. The aim was also to switch from a double-wall design to a cooled tubular lining.

The project:

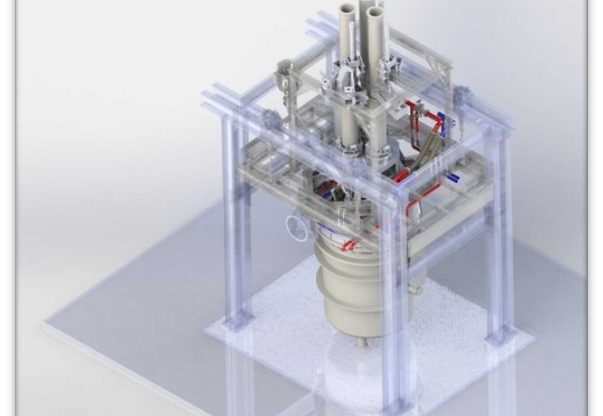

With all the information we had about the client’s infrastructure and the requirements they had specified for the new room, we visited the client’s premises to conduct our study. The aim was to study the feasibility of the project.

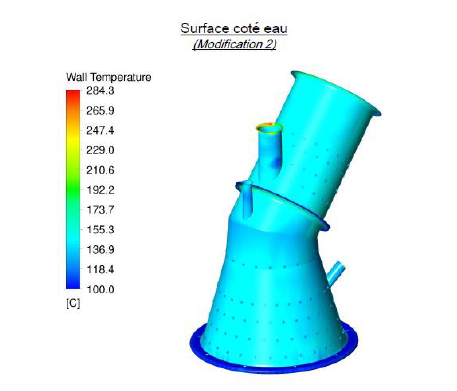

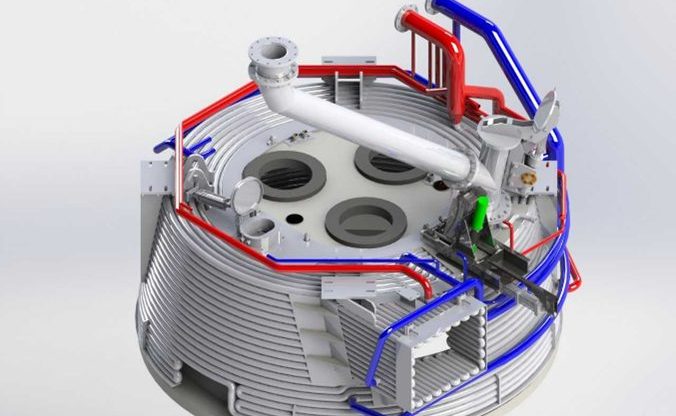

Once the visit was made and the study carried out, we provided the customer with a 3D model of the part using our drawing and calculation software (Solidworks, ANSYS). This enabled us to put the part into perspective within the client’s infrastructure.

(3D of the pocket oven cover)

When the validation of all the parts was obtained, we designed the new plans of the vault itself and the accessories. We also defined the new water circuits with the characteristics available on the existing installation.

The results:

As far as the results of the project are concerned, we have :

- Removed the refractory vault and its vault ring

- Replaced the double-wall cover design with a tubular design

- Relocated the SAS of the additions between electrodes 2&3

- Retained the guiding principles & SAS PTE

Bonus :

- The tube vault was made in a truncated cone shape with joined tubes to suit the customer’s requirements

- An opening in the tubular casing for SAS PTE and SAS additions connections, we also added a space for a camera to see what is going on inside

- The water supply from the vault manifolds is made with stainless steel hoses and isolation valves

Pocket furnace cover integrated in the steel mill infrastructure (3D)