Moving and replacing a 10 tonne plus, 5 metre diameter cooled vault roof is not a simple matter for a steel mill.

Cooled vaults are installed to capture the very high temperature erosive fumes from the molten steel in the arc furnaces. Their weights and sizes can differ depending on the installation, we have dealt with sizes ranging from 4 to 8 metres in diameter and weighing from 8 to over 30 tonnes.

These are strategic wear parts, their life span varies according to the process. They are replaced during the maintenance shutdowns of the plants in summer.

In order to increase their service life but also to make them more manageable during maintenance and panel replacement operations, SCCM ALP (re)designs and develops arc furnace vaults that are fully adapted to the company’s process, taking into account the existing cooling installations.

This was the explicit request of a large French steel company that wanted a cooled vault with a longer service life and greater manoeuvrability (during maintenance and panel replacement operations).

We have taken all this information into account and produced :

- A panel cut adapted to thermal stresses (hot spot) = increased durability

- Radial cutting of the panels to limit the number of accessories (elbows and “caps”) = reduction of pressure losses, economic aspect

- A series connection of the elbow to the vault with the least used panels = elimination of the “gap” between the vault and the elbow, thus limiting smoke leaks

- Optimisation of panel fasteners = easier maintenance

- Optimisation of the water circuit connections = optimal cooling of the panels and therefore of the smoke

All these operations have allowed us to optimise the hydraulic characteristics of the device and to make the room easier to use during maintenance operations (e.g. replacement of panels).

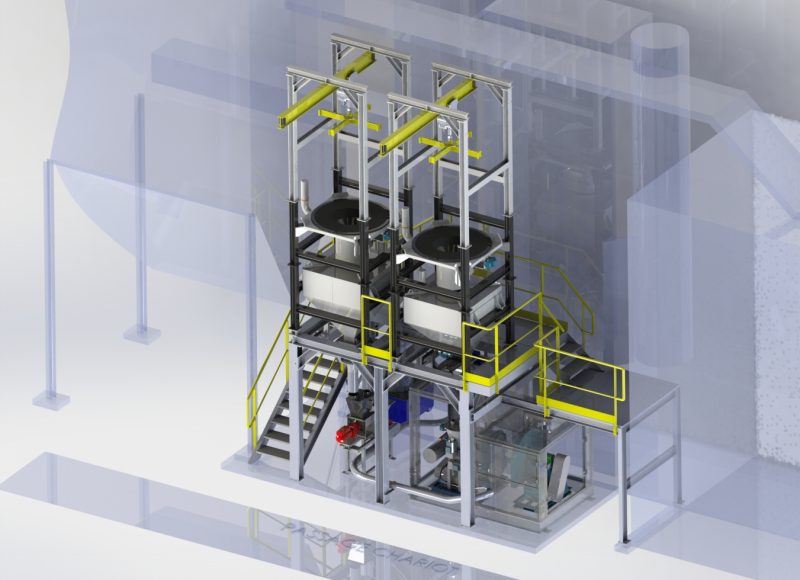

Beforehand, we carried out a complete thermal and hydraulic study of the room to allow a theoretical validation of the hypotheses. (e.g. image)

Once the part was finished, we tested it on our test bench. This showed us that the part was of good quality and that it would meet all the desired expectations.