PRESENTATION

Since the beginning of April, SCCM ALP is pleased to work with the Dutch company SOFIS, becoming their French distributor.

SOFIS is a manufacturer of valve control systems for mechanical interlocks, also portable actuators and valve position indicators.

It is the result of a merger made in 2016. Smith Flow Control (established 1985, UK) and Netherlocks Safety Systems (established 1993, NL) merged. Two world leaders in the field of valve interlocking have joined forces under the name SOFIS.

Over the years, they have developed into specialists, securing and optimising manual process safety systems and solutions for smart valve operations.

Due to SCCM ALP’s historical presence with customers with critical high-temperature processes and the geographical presence on the French market, the two companies have naturally come together and have concluded a distribution agreement as of the beginning of April 2022.

MAIN PRODUCTS

The main products by SOFIS are :

- Valve interlocks

- Portable valve actuator

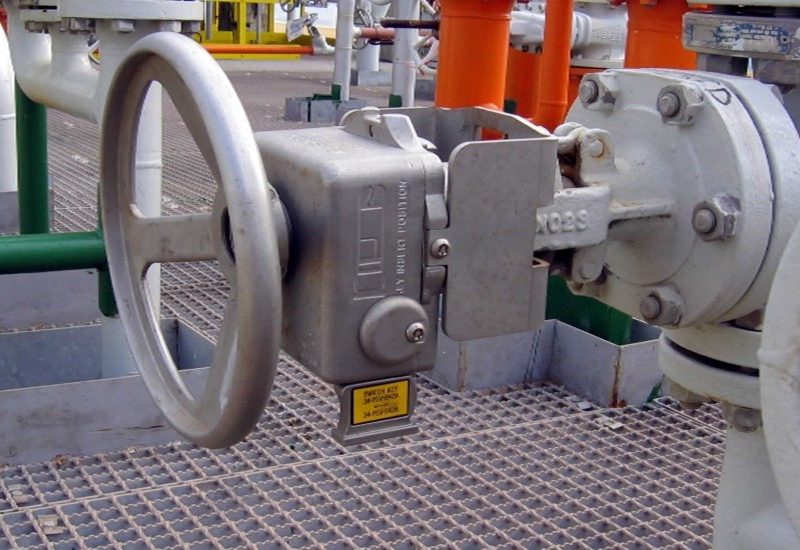

- Valve position indicator

VALVE INTERLOCKS

Using interlocks, you only allow the correct valve to be opened or closed in the correct sequence. You guide your operators every step of the way – there is no bypassing the system. Your valves are operated using a linear key, taking your operators through a specific process, following a predefined sequence, with unique keys for each step.

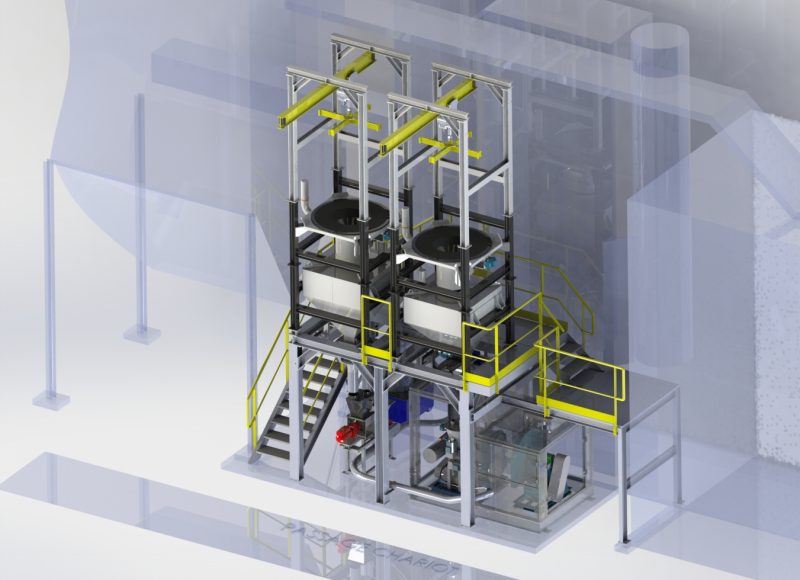

PORTABLE VALVE ACTUATOR

The Power Wrench portable actuator reduces valve operating time by up to 80% and improves efficiency when operating manual valves. Install the drive plate with u-bolts, connect the Power Wrench portable actuator to an air supply and you are ready to go!

VALVE POSTION INDICATOR

VPI is a high-performance switch box for manual multiturn valves. It detects when valves have reached their open or closed position and sends a signal to your DCS. This valuable information about manual assets enriches your control system’s capabilities. It helps to further optimize your process performance, and prevents safety issues or product contamination caused by incorrect valve line-ups.

THE GOAL

The principle of these products is to improve industrial safety standards to provide safer facilities for your employees and the environment.

This quality objective is at the heart of everything they do and it is achieved through these 3 steps:

- The design of high quality safety products

- Manufacturing these products according to a standardised process

- Guaranteed delivery on time