Issue:

The SITOM of an important city in the Rhône-Alpes region contacted SCCM ALP for the following problem: its incinerator treats its semi-wet fumes with lime milk. However, the latter is subject to pollution peaks in HCl (hydrochloric acid) and SO2 (sulphur dioxide) on the 2 incineration lines, which forces it to call in a specialist.

Suggested solutions from SCCM ALP:

After analysis of the existing process:

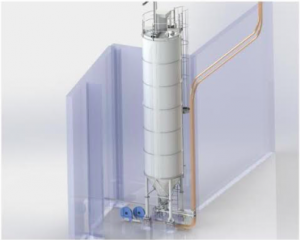

- Installation of a slaked lime silo equipped with 2 dosing screws and 2 pneumatic transport lines (1 common silo, 1 screw and 1 pneumatic transport per line)

- Optimisation of the operation of existing installations (milk of lime treatment)

- Injection of hydrated lime into the flue gas ducts at the reactor inlet

- Automatic reagent injection to prevent pollution thresholds from being exceeded

Noted improvements:

- Reduction of daily emissions during peaks:

Lowering of the threshold to 7mg/Nm3 HCl (legal obligation: 10mg/Nm3)

Lowering of the threshold to 35mg/Nm3 SO2 (legal obligation: 50mg/Nm3)

Lowering of the threshold to 35mg/Nm3 SO2 (legal obligation: 50mg/Nm3)

THIS NEWS MAY ALSO INTEREST YOU:

04.09.2023

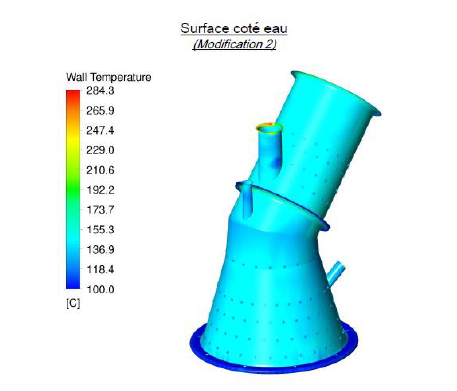

SCCM ALP carries out thermofluidic and thermomechanical numerical simulation to validate the behaviour of critical parts in cooled elements.

Read more